A guided cylinder is a type of linear actuator that combines the functionality of a traditional pneumatic or hydraulic cylinder with integrated guide rails or rods. These guide rails ensure smooth, stable, and precise linear motion, even under heavy loads or high forces. Guided cylinders are widely used in applications where misalignment, buckling, or side loads are a concern.

A guided cylinder is a type of linear actuator that combines the functionality of a traditional pneumatic or hydraulic cylinder with integrated guide rails or rods. These guide rails ensure smooth, stable, and precise linear motion, even under heavy loads or high forces. Guided cylinders are widely used in applications where misalignment, buckling, or side loads are a concern.

To be mounted the workpiece from three directions

| Port Sizes: | 10,16,20,25,32 |

| Acting Type: | Double |

| Operating Pressure: | 0.15~1.0MPa |

| (22~145psi) | |

| Proof pressure: | 1.5MPa(215psi) |

| Temperature: | -20~70°C |

| Speed range: | 30~500 mm/s |

| Adjustable stroke: | -5~0 mm |

| Max. stroke length: | 200mm |

| Tolerance: | >1.5 mm |

Two group of air intake and outlet at two side of cylinder

| Port Sizes: | 6,10,16,20,25,32 |

| Acting Type: | Double |

| single pull | |

| Operating Pressure: | 0.15~1.0MPa |

| (22~145psi) | |

| Proof pressure: | 1.5MPa(215psi) |

| Temperature: | -20~70°C |

| Speed range: | 30~500 mm/s |

| Max. stroke length: | 200mm |

| Tolerance: | >1.5 mm |

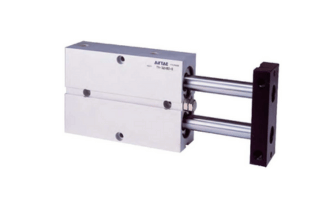

Drive unit and guide unit are in same barrel

| Port Sizes: | 6,10,12,16,20,25, |

| Port Sizes: | 32,40,50,63,80,100 |

| Acting Type: | Double |

| Operating Pressure: | 0.15~1.0MPa |

| (22~145psi) | |

| Proof pressure: | 1.2~1.5MPa(215psi) |

| Temperature: | -20~70°C |

| Speed range: | 30~500 mm/s |

| Max. stroke length: | 250mm |

| Tolerance: | >1.5 mm |