In today's rapid global market, the demand for efficient and reliable warehousing solutions is greater than ever. As e-commerce expands dramatically and supply chains become more complex, businesses turn to automated warehousing to remain competitive. This article explores the future of automated warehousing, the latest developments in warehouse automation, and how Itoh Denki is leading the way with innovative approaches.

Warehouse automation is evolving rapidly, driven by technological advancements and the need for efficiency, accuracy, and cost savings. Here are some of the latest trends shaping the future of automated warehousing:

AI and machine learning algorithms are being used to optimize warehouse operations. These technologies enable predictive maintenance of equipment, demand forecasting, and inventory management, resulting in reduced downtime and improved efficiency.

Computer Vision systems are enhancing the accuracy of picking and packing processes by enabling robots to recognize and handle a wide variety of products with precision.

The Internet of Things (IoT) is transforming warehouses into smart, interconnected environments. Sensors and IoT devices provide real-time data on inventory levels, equipment performance, and environmental conditions, enabling better decision-making and proactive maintenance.

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are revolutionizing material handling by automating the transport of goods within warehouses. These robots are equipped with advanced sensors and navigation systems, allowing them to operate safely alongside human workers.

Collaborative Robots (Cobots) are designed to work alongside humans, enhancing productivity and reducing the physical strain on workers. Cobots can perform repetitive tasks such as picking, packing, and sorting, freeing up human workers for more complex and value-added activities.

With growing emphasis on sustainability, warehouses are adopting energy-efficient solutions and green technologies. Automated systems are designed to minimize energy consumption and reduce carbon footprints, contributing to overall sustainability goals.

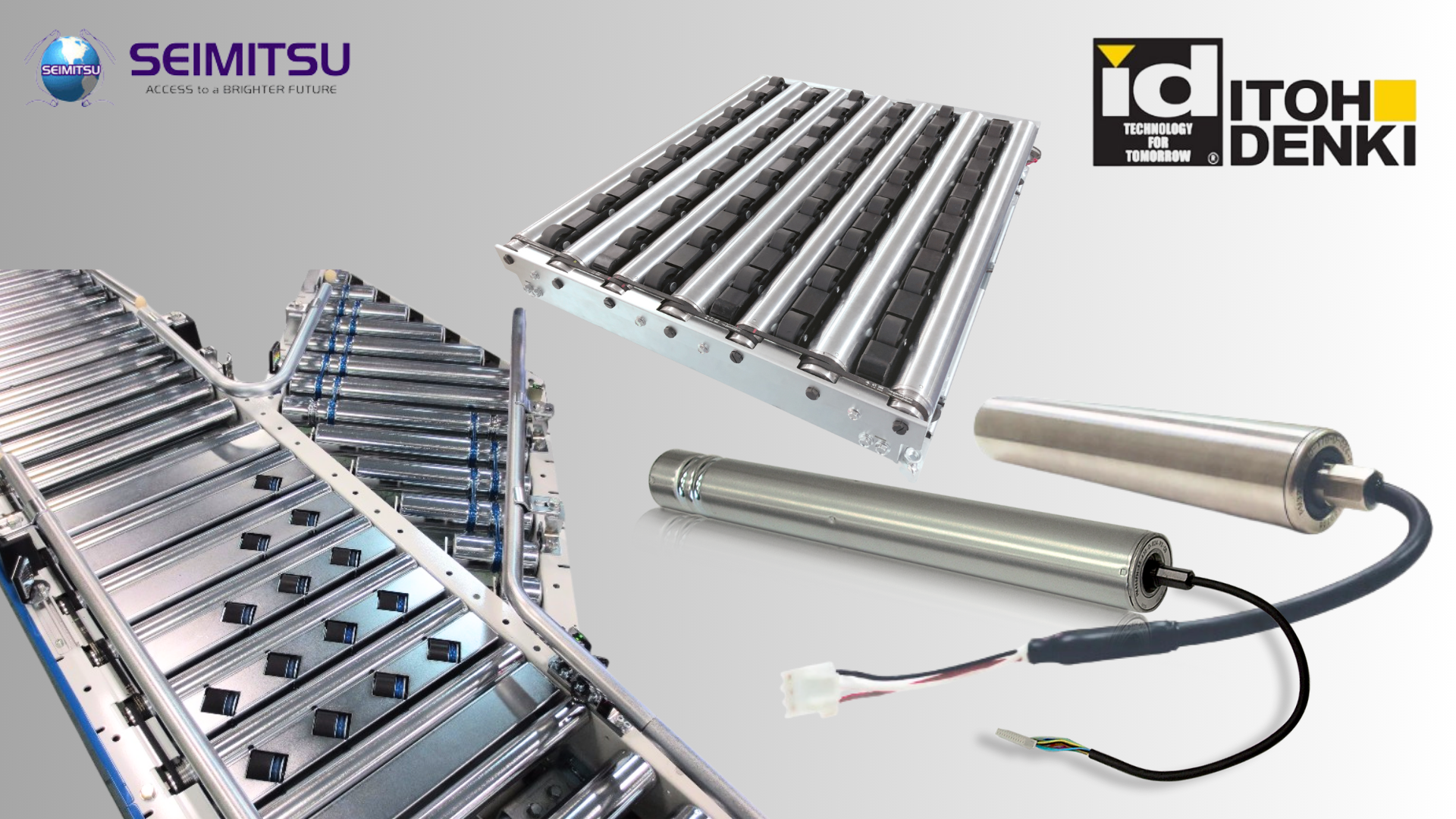

Itoh Denki has been at the forefront of warehouse automation for decades, known for its pioneering developments in motorized conveyor rollers and other innovative solutions. Here’s how Itoh Denki products are leading the way in automation:

Itoh Denki’s MDR technology is a game-changer in conveyor systems. These rollers are equipped with built-in motors, allowing for precise control of speed and torque. MDR systems are modular and scalable, making them ideal for dynamic warehouse environments.

The energy-efficient design of MDRs reduces power consumption, aligning with the trend towards sustainability. Additionally, their quiet operation enhances the working environment for warehouse staff.

Itoh Denki's conveyor modules are designed to enhance the efficiency and productivity of warehouse operations. These modules integrate advanced motorized drive rollers (MDR) that offer precise control and energy efficiency.

The conveyor modules are highly modular, allowing for easy integration into existing systems and scalability to meet changing warehouse demands. This flexibility is crucial for businesses looking to adapt to fluctuating workloads and evolving market conditions.

Safety is a top priority for Itoh Denki. The conveyor modules are designed with safety features such as emergency stop functions and protective coverings to prevent accidents. The robust construction ensures long-term reliability and minimal disruptions to operations.

By leveraging these advanced features, Itoh Denki's conveyor modules contribute significantly to the optimization of warehouse automation, helping businesses achieve greater efficiency, cost savings, and enhanced operational capabilities.

Seimitsu has established itself as a trusted name in the Indian market, providing high-quality industrial automation components and solutions. As an authorized distributor of Itoh Denki products in India, Seimitsu plays a crucial role in bringing Itoh Denki’s advanced automation technologies to the region. By leveraging Seimitsu's extensive distribution network and industry expertise, businesses across India can now access Itoh Denki’s innovative solutions to enhance their warehouse operations.

Seimitsu offers a comprehensive range of Itoh Denki products, including motorized drive rollers, Conveyor modules, etc. Their dedicated support team ensures that customers receive expert guidance and after-sales service, helping them maximize the benefits of Itoh Denki technologies.

The future of automated warehousing is bright, with advancements in robotics , AI, IoT, and sustainability driving the industry forward. Itoh Denki stands out as a leader in this space, offering innovative solutions that enhance efficiency, accuracy, and energy savings. The positive experiences of their customers underscore the tangible benefits of adopting Itoh Denki technologies. With Seimitsu as an authorized distributor in India, businesses in the region are well-positioned to leverage these cutting-edge solutions and stay competitive in the evolving landscape of warehouse automation. As warehouses continue to evolve, Itoh Denki and Seimitsu will undoubtedly play a crucial role in shaping the future of automation.